Temperature’s Effect on Working Pressure

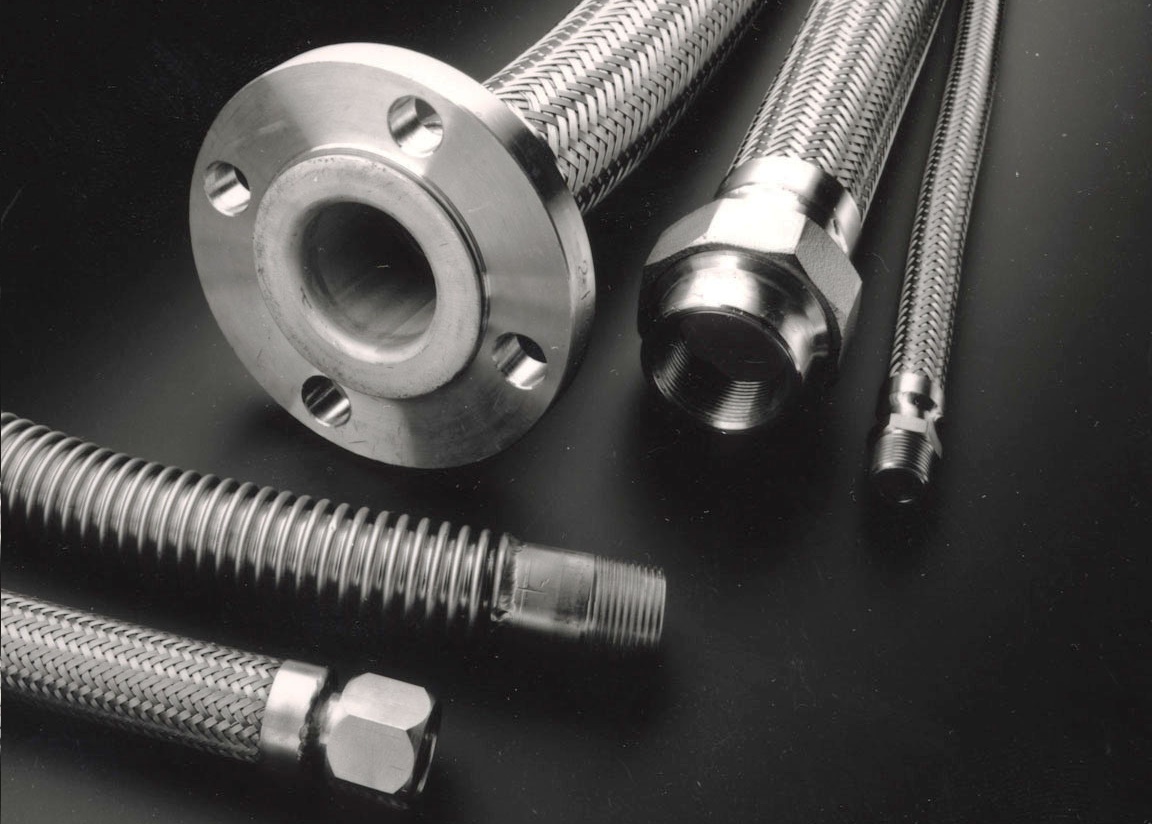

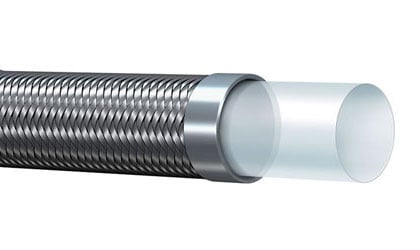

When selecting the components of a metal hose assembly, care must be taken to correctly match each component to the intended working pressure of the application. Because corrugated metal hose can handle extreme temperatures better than other hose types, it is important to know how these temperatures (internal or external) effect the working pressure of a corrugated metal hose assembly.

Here’s a quick reminder of how to select hose and fittings that will handle the combined pressure and temperature. As the temperature increases, the maximum allowable pressure rating of the assembly decreases. The percentage of this decrease depends on the alloy of the components and the temperature to which they will be exposed. The NAHAD Hose Safety Institute Handbook lists the guidelines for derating the working pressure of hose and braid when used at elevated temperatures.

Just as a chain is only as strong as its weakest link, a corrugated assembly is only as strong as its weakest component. Once the maximum temperature to which the assembly will be exposed is determined, hose and fittings must then be selected to accommodate this pressure/temperature combination. Using the derating chart, match the alloy(s) of the hose and braid to the maximum temperature to which they will be exposed in order to obtain the proper derating factor. Then, multiply the hose’s Maximum Working Pressure by the most limiting derating factor (i.e. the lowest multiplier of the hose and braid alloys) to obtain the reduced working pressure. This procedure should also be followed for the other components of the assembly (fittings, accessories, etc.), according to the manufacturers’ recommendations for their products.

If a hose is being used for extreme low temperatures such as cryogenics, corrugated metal hose is again the best choice. Stainless steel retains its strength at low temperatures, without a marked increase in brittleness. Certain alloys, such as carbon steel, are not recommended for low temperature applications.

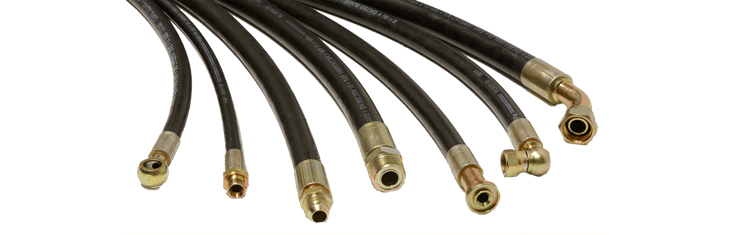

There are other factors that may limit the working pressure of an assembly, such as the fitting attachment technique or dynamic pressure changes. The HSI Handbook addresses some of these considerations, or contact the manufacturer for additional assistance.

About Frank Caprio

Frank Caprio is the Corporate Trainer/Major Market Specialist at Hose Master, LLC. He has more than 35 years of experience in hydraulic, industrial, metal hose and expansion joint products and applications, and is the “Dean” of Hose Master’s training program, Hose Master University. He is nationally recognized as a leading authority in metal hose, and has authored various articles for industry publications and become a sought-after source for industry facts and trends. Frank is a member of AIST, ASM International, and ASTM International and is on NAHAD’s Technical Committee for Corrugated Metal Hose.